How Do Top Heat Exchanger Suppliers Ensure Quality and Efficiency?

Sourcing High-Quality Materials

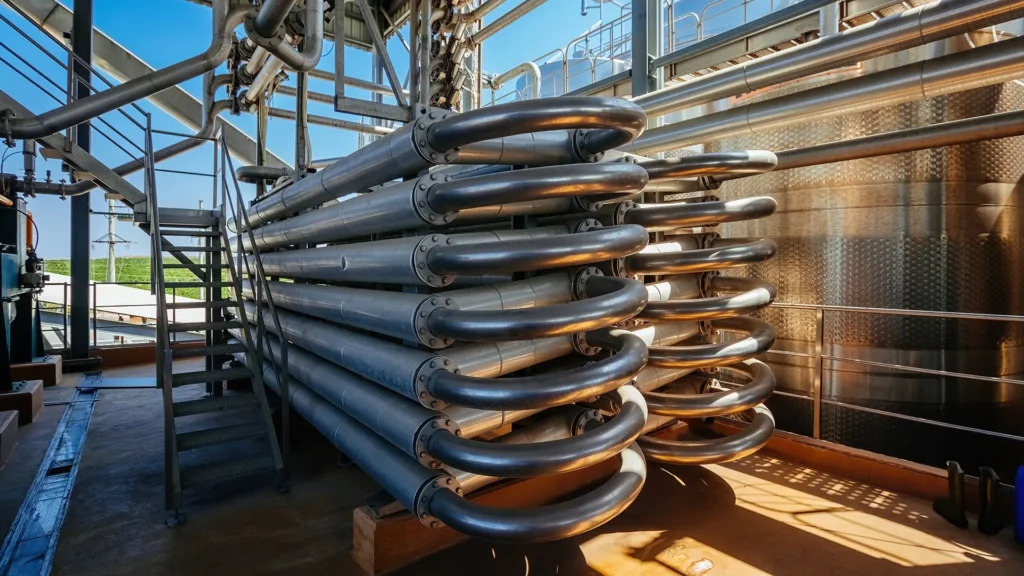

The satisfactory of a warmness exchanger starts offevolved with the materials used. Top heat exchanger suppliers cognizance on sourcing awesome materials that provide durability, performance, and resistance to corrosion. Materials such as stainless-steel, aluminum, and titanium are regularly selected for his or her superior homes. Stainless metal, as an example, presents high-quality corrosion resistance and mechanical power, while aluminum offers lightweight construction with remarkable thermal conductivity. Suppliers cautiously vet their providers and perform stringent first-rate exams to make sure the materials meet enterprise requirements. This attention to detail ensures that the heat exchangers carry out reliably even in disturbing conditions.

Adherence to Industry Standards

Maintaining best and safety in warmness exchangers requires compliance with globally identified requirements. Leading warmness exchanger suppliers adhere to certifications such as ASME (American Society of Mechanical Engineers), ISO 9001 (Quality Management Systems), and TEMA (Tubular Exchanger Manufacturers Association). These certifications make certain that the design, substances, and production strategies meet strict performance and protection tips. Suppliers regularly go through third-party inspections and audits to hold compliance. Adhering to such standards now not only builds consumer agree with however also ensures that warmness exchangers function efficiently throughout industries.

Implementing Advanced Manufacturing Processes

Advanced manufacturing methods play a great position in making sure the fine and efficiency of warmth exchangers. Top suppliers leverage modern-day technology including automatic welding, Computer-Aided Design (CAD), and actual-time fine control systems. Automated welding ensures precision and leak-unfastened joints, even as CAD facilitates layout custom designed answers that maximize overall performance. Additionally, sensors and digital gear reveal the manufacturing process to cast off mistakes and make certain accuracy. By incorporating those superior strategies, warmness exchanger suppliers supply gadget that meets precise specs at the same time as minimizing waste and inefficiencies.

Thorough Performance Testing

Testing is a essential step in the manufacturing of heat exchangers, ensuring that they meet each quality and efficiency requirements. Top warmness exchanger providers conduct rigorous tests, together with stress trying out, thermal overall performance evaluation, and vibration simulations. Pressure checking out identifies leaks or weaknesses inside the device, even as thermal overall performance testing confirms the exchanger’s potential to transfer warmth efficiently. Durability exams assess how properly the device plays under operational stress. This thorough trying out ensures that the heat exchangers will perform reliably in real-international programs, giving customers self belief of their purchase.

Customization for Better Efficiency

Every enterprise has unique requirements, and one-size-fits-all answers frequently fall short. Leading warmth exchanger providers offer customization options to optimize their merchandise for particular wishes. These alternatives include tailored sizes, fabric selection, and performance-centered designs. Customization guarantees that heat exchangers perform at peak performance within their supposed environment, whether or not they're utilized in compact spaces or beneath high-pressure conditions. By working carefully with clients, suppliers create answers that maximize strength financial savings, reduce operational prices, and decorate normal overall performance.

Role of Screw Vacuum Pumps in Heat Exchanger Systems

Screw vacuum pumps are regularly used alongside warmness exchangers to enhance overall performance and performance. These pumps create a vacuum by way of casting off air or unwanted gases, which enhances the heat switch procedure. By lowering pressure, screw vacuum pumps allow heat exchangers to operate extra efficaciously, making sure ultimate cooling and fluid flow. This integration reduces power intake and complements overall gadget performance. Top providers often advise or integrate well suited equipment, like screw vacuum pumps, to create a whole and excessive-acting answer for their clients.

Ensuring Longevity and Reliability

Quality and performance are incomplete with out lengthy-time period durability. Top heat exchanger providers rent strategies that enhance the lifespan of their products. Protective coatings, as an instance, are implemented to prevent corrosion in harsh environments. Stress analysis is used to perceive and improve susceptible factors for the duration of the layout process, ensuring that the system can cope with disturbing conditions. High-first-class sealing strategies are also carried out to save you leaks under strain. By specializing in reliability, suppliers make certain their heat exchangers perform effectively for years, lowering maintenance charges and downtime.

Conclusion: Why Does Supplier Quality Matter?

Selecting the proper warmth exchanger suppliers is vital to ensuring both great and efficiency. From sourcing the best substances and adhering to strict enterprise standards to imposing superior production and checking out techniques, pinnacle suppliers assure their merchandise carry out reliably and efficaciously. Customization and complementary technology, together with screw vacuum pumps, further decorate the cost of heat exchangers. By prioritizing nice and performance, these suppliers assist industries achieve higher overall performance, strength savings, and long-term reliability. Before making a decision, clients should examine how suppliers meet these benchmarks to make certain they are making an investment in the high-quality solution for his or her needs.

uklalyrics

uklalyrics