Nitto Seiko Automated Screwing Solutions: Revolutionizing Assembly Processes

In today’s fast-paced manufacturing landscape, efficiency and precision are paramount. Nitto Seiko, a leader in fastening technology, offers advanced automated screwing solutions designed to meet the demands of modern production lines. These solutions enhance operational efficiency, reduce labor costs, and improve product quality, making them indispensable for manufacturers across various industries.

Overview of Nitto Seiko Automated Screwing Solutions

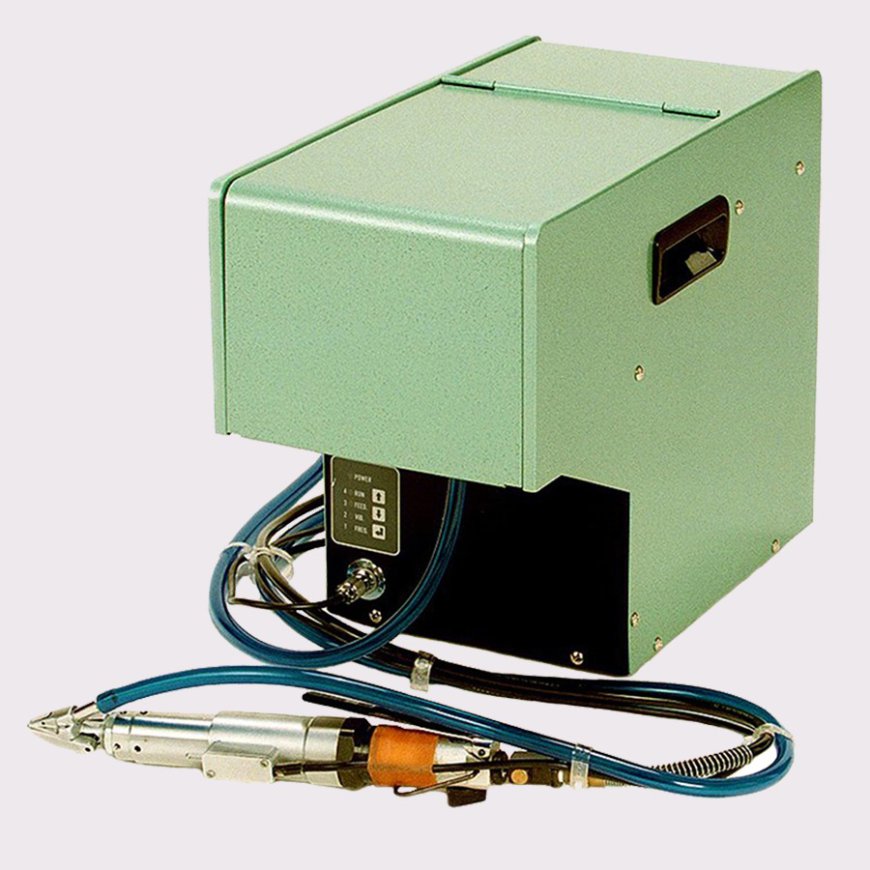

Nitto Seiko's automated screwing solutions encompass a range of products, including electric screwdrivers, torque controllers, and assembly systems. The company leverages its extensive expertise in fastening technology to develop solutions that cater to the unique needs of each client. Their automated systems are particularly beneficial in high-volume production environments, where consistent quality and speed are critical.

The core of Nitto Seiko's automated screwing solutions is their commitment to precision and reliability. By utilizing advanced technologies, these systems ensure that every screw is driven with the correct torque and alignment, minimizing the risk of stripped screws and ensuring secure assembly. This level of precision not only enhances product quality but also significantly reduces the time spent on manual inspections and corrections.

Key Features and Benefits

-

Advanced Torque Control: One of the standout features of

is their sophisticated torque control systems. These systems allow for precise adjustments to be made based on the specific requirements of each application. This capability is vital in industries where the integrity of the assembly is critical, such as automotive and electronics.

-

Increased Productivity: Automation is synonymous with increased productivity. Nitto Seiko’s solutions facilitate faster assembly processes, allowing manufacturers to meet higher production targets without compromising quality. This efficiency translates into shorter lead times and the ability to respond quickly to market demands.

-

Versatility Across Industries: Nitto Seiko’s automated screwing solutions are versatile and applicable across various sectors, including automotive, consumer electronics, medical devices, and more. The adaptability of their products ensures that manufacturers can implement these solutions regardless of their specific industry needs.

-

User-Friendly Interface: Understanding that not all operators are highly skilled, Nitto Seiko designs its systems with user-friendly interfaces. This allows for easy training and operation, minimizing the learning curve and ensuring that teams can effectively use the equipment from day one.

-

Data Integration and Monitoring: Modern manufacturing processes rely heavily on data analytics to drive improvements. Nitto Seiko's automated screwing systems can be integrated with manufacturing execution systems (MES) to provide real-time monitoring and data collection. This capability enables manufacturers to analyze performance metrics, identify bottlenecks, and optimize their operations for greater efficiency.

-

Durability and Reliability: Built to withstand the rigors of industrial environments, Nitto Seiko’s automated systems are designed for durability and long-term reliability. This robustness reduces the frequency of maintenance and replacement, contributing to lower operational costs.

Applications of Nitto Seiko Automated Screwing Solutions

Nitto Seiko’s automated screwing solutions have a broad range of applications, highlighting their versatility:

-

Automotive Manufacturing: In the automotive industry, precise fastening is critical for safety and performance. Nitto Seiko's solutions help ensure that components are securely assembled, reducing the risk of failure in the field.

-

Consumer Electronics: The rapid evolution of consumer electronics demands quick assembly processes without sacrificing quality. Nitto Seiko’s systems enable manufacturers to keep pace with market demands while maintaining high standards.

-

Medical Devices: In the medical field, the reliability of devices is paramount. Nitto Seiko’s automated screwing solutions provide the precision necessary for the assembly of critical medical devices, ensuring they meet stringent regulatory requirements.

-

Industrial Equipment: For manufacturers of industrial machinery, Nitto Seiko's solutions enhance assembly line efficiency, allowing for faster production cycles and reduced labor costs.

Sustainability and Environmental Responsibility

As global awareness of environmental issues grows, manufacturers are increasingly seeking sustainable practices. Nitto Seiko is committed to reducing waste and energy consumption through its automated solutions. By enhancing efficiency and minimizing errors, their systems contribute to a more sustainable manufacturing process. Furthermore, Nitto Seiko emphasizes the use of eco-friendly materials in its products, aligning with the industry’s shift towards sustainability.

Conclusion

Nitto Seiko automated screwing solutions represent a significant advancement in fastening technology, offering manufacturers the tools they need to thrive in a competitive landscape. With their emphasis on precision, productivity, and versatility, these solutions are tailored to meet the diverse needs of various industries.

By integrating Nitto Seiko's systems into production lines, manufacturers can enhance product quality, streamline processes, and reduce costs, all while supporting sustainable practices. As the manufacturing industry continues to evolve, Nitto Seiko remains at the forefront of innovation, providing automated solutions that pave the way for future advancements in assembly technology.