PP Sheets: A Versatile Solution for Diverse Industrial Applications

Polypropylene (PP) sheets have emerged as one of the most versatile materials in industrial and commercial use. These lightweight, durable, and cost-effective sheets are made from polypropylene, a thermoplastic polymer known for its excellent mechanical properties and chemical resistance. With applications ranging from packaging and construction to automotive and healthcare, PP sheets have become indispensable in modern manufacturing. In this Pulkit Plastic Products, we will delve into the features, advantages, and applications of PP sheets, exploring their relevance in today’s market. We'll also discuss factors influencing PP sheet price and highlight how polypropylene sheets manufacturers and suppliers are driving innovation.

What Are PP Sheets?

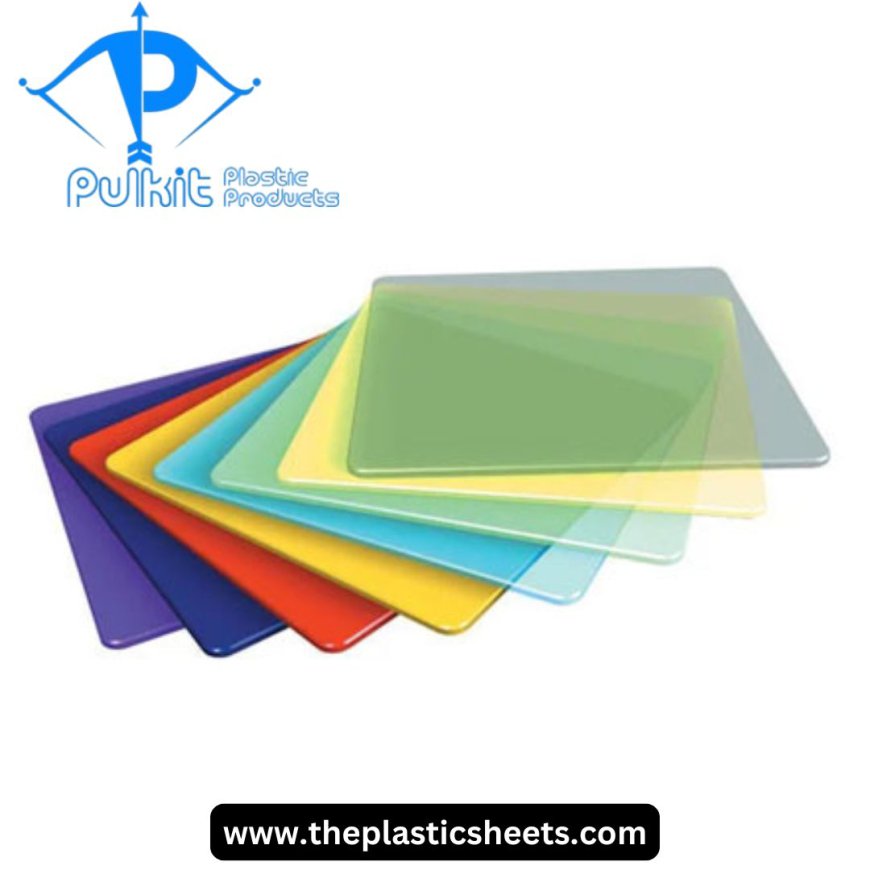

PP sheets are flat, rigid plastic sheets manufactured from polypropylene. This material is highly valued for its combination of lightweight and robust properties, making it suitable for a wide array of applications. These sheets are available in various thicknesses, sizes, and finishes to cater to different industry needs.

Commonly used for packaging, signage, and protective layers, PP sheets offer high impact resistance and excellent thermal stability. Their ability to withstand harsh chemicals and weather conditions makes them a preferred choice for outdoor and industrial applications. Leading polypropylene sheets manufacturers also offer customized options, including textured or laminated finishes, to meet specific client requirements.

Key Features of Polypropylene Sheets

PP sheets stand out due to their unique properties, which make them suitable for demanding environments:

-

Lightweight and Durable

One of the most appealing features of PP sheet price is their lightweight nature, which does not compromise their strength. This combination ensures ease of handling and long-lasting performance. -

Chemical Resistance

PP sheets are highly resistant to acids, alkalis, and organic solvents, making them ideal for applications in laboratories, chemical processing plants, and other industries dealing with corrosive substances. -

Thermal Stability

With a high melting point, polypropylene sheets can withstand temperatures up to 100°C, making them suitable for applications requiring thermal resistance. -

Flexibility and Customization

Polypropylene sheets can be easily cut, shaped, or welded, offering immense flexibility for manufacturers and end-users. -

Eco-Friendly

Polypropylene is 100% recyclable, making PP sheets an environmentally friendly choice for industries aiming to reduce waste.

Applications of PP Sheets Across Industries

The versatility of PP sheets has led to their adoption across numerous sectors. Below are some of their key applications:

-

Packaging Industry

In packaging, PP sheets are used for creating reusable boxes, containers, and liners. Their lightweight and moisture-resistant properties make them ideal for storing and transporting goods. -

Construction and Signage

Construction sites rely on PP sheets for shuttering, insulation, and temporary barriers. In the advertising sector, these sheets are used for outdoor signage due to their durability and weather resistance. -

Automotive Industry

Automotive manufacturers use polypropylene sheets for interior linings, protective panels, and lightweight components, reducing the overall weight of vehicles while maintaining structural integrity. -

Healthcare and Pharmaceuticals

PP sheets are utilized for sterilized trays, protective coverings, and medical-grade storage solutions, thanks to their non-toxic and chemically inert nature. -

Stationery and Crafts

Polypropylene sheets are popular in the creation of file folders, binders, and craft items due to their ease of customization and vibrant color options.

Factors Influencing PP Sheet Price

The cost of PP sheets can vary based on several factors, making it essential for buyers to understand these variables:

-

Thickness and Size

The thickness of the sheet significantly impacts its price. Thicker sheets require more material and processing, resulting in higher costs. -

Customization

Custom features, such as specific colors, textures, or UV-resistant coatings, can increase the PP sheet price. -

Quantity and Bulk Orders

Buying in bulk from polypropylene sheets suppliers often reduces the per-unit cost due to economies of scale. -

Raw Material Costs

Fluctuations in the price of polypropylene resin, the primary raw material, directly affect the cost of the sheets. -

Manufacturing Process

Advanced manufacturing techniques, such as co-extrusion or laminated finishes, add to production costs but offer superior quality and performance.

Role of Polypropylene Sheets Manufacturers and Suppliers

Leading polypropylene sheets manufacturers play a crucial role in ensuring consistent quality and innovation. These manufacturers invest in state-of-the-art machinery and adhere to international standards to produce sheets that meet diverse industry needs.

Suppliers, on the other hand, act as the bridge between manufacturers and end-users. They ensure timely delivery, provide technical support, and often offer competitive pricing for bulk orders. Many suppliers now focus on eco-friendly distribution practices, including the promotion of recyclable materials and sustainable packaging solutions.

Advantages of Choosing Polypropylene Sheets

Businesses and individuals opting for Polypropylene sheets manufacturers enjoy several benefits, including:

-

Cost-Effectiveness

Compared to other materials like metal or glass, PP sheets offer a budget-friendly alternative without compromising on quality. -

Longevity

With high resistance to wear and tear, PP sheets are ideal for long-term applications, reducing replacement costs. -

Ease of Maintenance

These sheets are easy to clean and maintain, even in harsh environments, making them a low-maintenance solution. -

Aesthetic Appeal

Available in a variety of colors and finishes, PP sheets can enhance the visual appeal of products, signage, or packaging. -

Eco-Conscious Choice

Being recyclable and reusable, polypropylene sheets align with global efforts to minimize environmental impact.

Sustainability and Future Trends in PP Sheets

The growing emphasis on sustainability has driven polypropylene sheets manufacturers to adopt greener production methods. Many manufacturers now use recycled polypropylene or introduce biodegradable additives to reduce the environmental footprint of their products.

Future trends include the development of lightweight yet stronger sheets and the integration of smart materials, such as UV-sensitive or heat-sensitive coatings. Innovations in manufacturing are also expected to enhance the recyclability and biodegradability of PP sheets, aligning with global sustainability goals.

With rising demand across industries and advancements in technology, the future of PP sheets is undoubtedly bright. They will continue to play a pivotal role in shaping industrial and consumer products, ensuring functionality and environmental responsibility.

Conclusion

The Polypropylene sheets suppliers have revolutionized industrial and commercial applications with their unmatched versatility, durability, and affordability. From packaging and construction to healthcare and automotive industries, polypropylene sheets manufacturers and suppliers have ensured a steady supply of high-quality sheets that meet diverse needs.

As the world shifts towards sustainable practices, the role of eco-friendly polypropylene sheets is becoming increasingly significant. Their recyclability and long lifespan make them a valuable resource in creating a circular economy. With continuous innovation and demand, PP sheets will remain a cornerstone material for industries worldwide.

Frequently Asked Questions (FAQs)

1. What is the typical lifespan of polypropylene sheets?

Polypropylene sheets are highly durable and can last for several years, depending on the application and exposure to environmental factors. UV-stabilized sheets are ideal for outdoor use to extend their lifespan.

2. How do I choose the right thickness for PP sheets?

The thickness of PP sheets depends on the intended application. For lightweight packaging, thinner sheets suffice, while construction or industrial uses may require thicker sheets for added strength and stability.

3. Are polypropylene sheets environmentally friendly?

Yes, polypropylene sheets are recyclable and can be repurposed for various applications, making them an eco-friendly choice. Many manufacturers also offer sheets made from recycled materials.

pulkitplasticproducts001

pulkitplasticproducts001