PU SANDWICH PANELS:

PU SANDWICH PANELS:

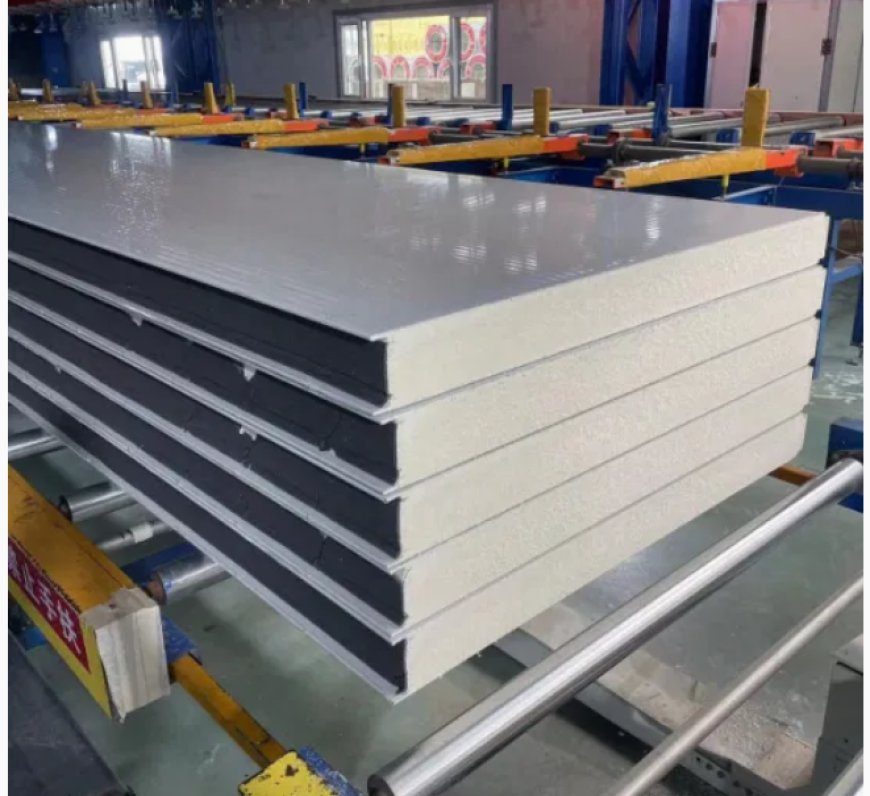

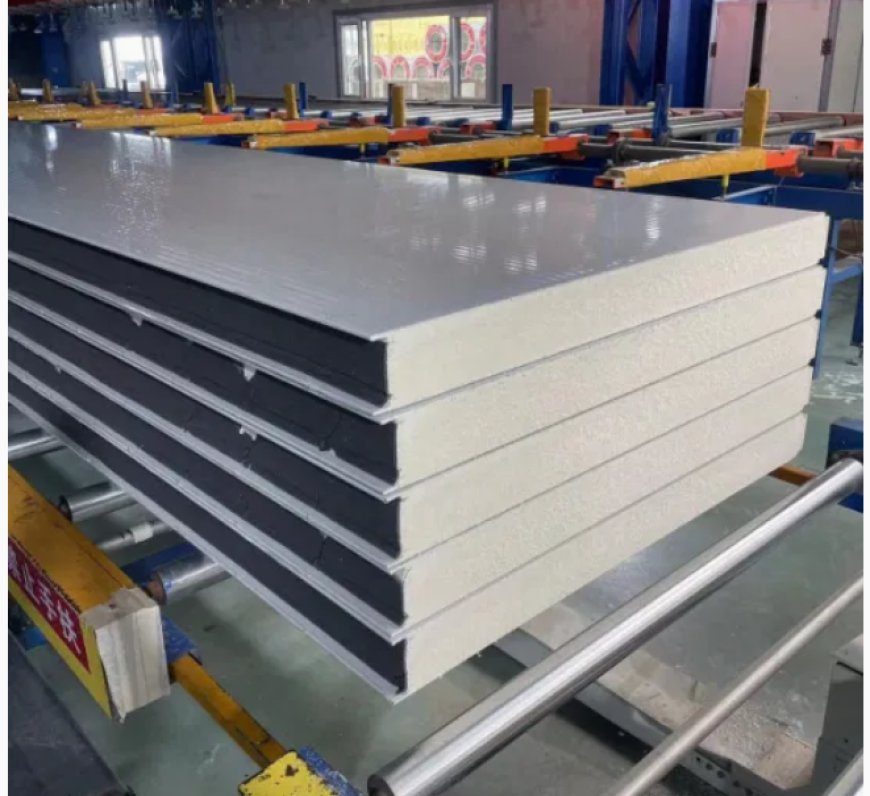

Polyurethane (PU) sandwich boards are broadly perceived for their adaptability and effectiveness in different development and protection applications. These boards are made out of two layers of outer material (normally metal, however can be aluminum, steel, or other) that sandwich a center produced using unbending polyurethane froth. The sandwich configuration gives underlying respectability, protection, and many different advantages, making PU boards profoundly advantageous in the development business.

The best engineering companies in pakistan give a large number of advantages that drive the nation's financial, social, and modern turn of events.

Warm Protection Effectiveness

One of the essential benefits of PU sandwich boards is their great warm protection properties. PU froth has a low warm conductivity, normally going between 0.019 to 0.024 W/mK. This makes it one of the most productive warm separators that anyone could hope to find. By utilizing PU boards in structures, the intensity move through walls, rooftops, and different designs can be limited, which prompts better temperature control inside.

For environments that experience outrageous intensity or chilly, the utilization of PU boards keeps a steady inner climate, fundamentally lessening the requirement for warming or cooling. This eventually brings down energy utilization and functional expenses, especially in energyconcentrated enterprises like cold storage spaces, distribution centers, and production lines. For homes, workplaces, and business structures, this implies better solace levels, decreased service bills, and a more modest natural impression.

Sturdiness and Underlying Strength

PU sandwich boards are profoundly strong, making them appropriate for long haul applications. The outer layers of the boards, which are generally produced using aroused steel or aluminum, give insurance from outside components like dampness, UV radiation, and actual effects. This guarantees that the boards can endure brutal ecological circumstances without losing their primary respectability. The center material, polyurethane froth, adds unbending nature to the board, further improving its solidarity.

These properties make PU boards ideal for modern structures, stockrooms, and horticultural designs, where both protection and toughness are vital. In regions with weighty snow, wind, or downpour, PU boards keep up with their presentation over significant stretches without requiring continuous fixes or support.

Lightweight and Simple to Introduce

Regardless of their solidarity and sturdiness, PU sandwich boards are lightweight contrasted with conventional structure materials like cement or block. This makes them more straightforward to deal with, transport, and introduce, which can lessen development time and expenses. In enormous scope projects like production lines or business structures, the lightweight idea of PU boards considers speedier gathering, prompting more limited development periods and quicker project finish.

The boards can be made in enormous aspects, which lessens the quantity of joints required during development. Less joints mean less open doors for warm spanning, guaranteeing better protection execution across the whole structure envelope.

Flexibility in Applications

PU sandwich boards are flexible and can be utilized in different development applications. They are regularly utilized for wall cladding, material, and roof frameworks in modern, business, and private structures. Their versatility pursues them a famous decision for:

Cold storerooms: Where it is significant to keep up with low temperatures.

Clean-rooms: For drug, biotech, and semiconductor ventures.

Preambled structures: For homes, workplaces, and compact lodges.

Agrarian structures: For pens, outbuildings, and food stockpiling.

Shopping centers, display areas, and office spaces.

The capacity to tweak PU boards to various thicknesses, varieties, and surface completions guarantees that they can meet explicit undertaking prerequisites. Also, the boards can be planned with heat proof properties by integrating added substances, which is fundamental for consenting to building wellbeing guidelines.

ATTENTION:For your factory,pu sandwich panel offer a practical, cost-effective, and energy efficient solution. They provide excellent insulation, structural durability, fire resistance, and sound control, making them ideal for the demands of industrial settings.

Impecuniousness to fire

While polyurethane itself is a combustible material, current PU sandwich boards are produced with heat proof properties. This is accomplished by involving fireretardant synthetic compounds in the polyurethane froth or by covering the boards with heat proof facings. The expansion of these fire-retardant layers guarantees that the boards are consistent with tough fire wellbeing guidelines in numerous locales.

Heat proof PU sandwich boards can defer the spread of flares, giving tenants extra chance to clear and firemen additional opportunity to control the blast. This causes them a more secure choice for structures that to require high fire insurance guidelines, like schools, clinics, and public structures.

Sound Protection

One more significant advantage of PU sandwich boards is their capacity to give sound protection. The thick design of polyurethane froth hoses commotion, which is especially significant in conditions with elevated degrees of sound contamination, like manufacturing plants, air terminals, and occupied metropolitan regions. By utilizing PU boards for walls, rooftops, or parcels, the transmission of commotion between various regions can be diminished, establishing a calmer and more agreeable climate for laborers or occupants.

This trademark likewise makes PU boards an alluring choice for theaters, show lobbies, and recording studios where sound control is basic.

End

Polyurethane (PU) sandwich boards offer many advantages, including excellent warm protection, underlying strength, imperiousness to fire, sound protection, and plan adaptability. Their lightweight nature and simplicity of establishment decrease development time and expenses, while their sturdiness guarantees long haul execution with negligible support. PU boards are likewise harmless to the ecosystem, with energy-saving properties that add to a decrease in fossil fuel byproducts. Their application across different enterprises, from cold capacity to private lodging, makes them an ideal answer for current development needs. In general, PU sandwich boards give a practical, manageable, and productive structure material that fulfills the needs of both private and modern undertakings.

PU SANDWICH PANELS:

Polyurethane (PU) sandwich boards are broadly perceived for their adaptability and effectiveness in different development and protection applications. These boards are made out of two layers of outer material (normally metal, however can be aluminum, steel, or other) that sandwich a center produced using unbending polyurethane froth. The sandwich configuration gives underlying respectability, protection, and many different advantages, making PU boards profoundly advantageous in the development business.

The best engineering companies in pakistan give a large number of advantages that drive the nation's financial, social, and modern turn of events.

Warm Protection Effectiveness

One of the essential benefits of PU sandwich boards is their great warm protection properties. PU froth has a low warm conductivity, normally going between 0.019 to 0.024 W/mK. This makes it one of the most productive warm separators that anyone could hope to find. By utilizing PU boards in structures, the intensity move through walls, rooftops, and different designs can be limited, which prompts better temperature control inside.

For environments that experience outrageous intensity or chilly, the utilization of PU boards keeps a steady inner climate, fundamentally lessening the requirement for warming or cooling. This eventually brings down energy utilization and functional expenses, especially in energyconcentrated enterprises like cold storage spaces, distribution centers, and production lines. For homes, workplaces, and business structures, this implies better solace levels, decreased service bills, and a more modest natural impression.

Sturdiness and Underlying Strength

PU sandwich boards are profoundly strong, making them appropriate for long haul applications. The outer layers of the boards, which are generally produced using aroused steel or aluminum, give insurance from outside components like dampness, UV radiation, and actual effects. This guarantees that the boards can endure brutal ecological circumstances without losing their primary respectability. The center material, polyurethane froth, adds unbending nature to the board, further improving its solidarity.

These properties make PU boards ideal for modern structures, stockrooms, and horticultural designs, where both protection and toughness are vital. In regions with weighty snow, wind, or downpour, PU boards keep up with their presentation over significant stretches without requiring continuous fixes or support.

Lightweight and Simple to Introduce

Regardless of their solidarity and sturdiness, PU sandwich boards are lightweight contrasted with conventional structure materials like cement or block. This makes them more straightforward to deal with, transport, and introduce, which can lessen development time and expenses. In enormous scope projects like production lines or business structures, the lightweight idea of PU boards considers speedier gathering, prompting more limited development periods and quicker project finish.

The boards can be made in enormous aspects, which lessens the quantity of joints required during development. Less joints mean less open doors for warm spanning, guaranteeing better protection execution across the whole structure envelope.

Flexibility in Applications

PU sandwich boards are flexible and can be utilized in different development applications. They are regularly utilized for wall cladding, material, and roof frameworks in modern, business, and private structures. Their versatility pursues them a famous decision for:

Cold storerooms: Where it is significant to keep up with low temperatures.

Clean-rooms: For drug, biotech, and semiconductor ventures.

Preambled structures: For homes, workplaces, and compact lodges.

Agrarian structures: For pens, outbuildings, and food stockpiling.

Shopping centers, display areas, and office spaces.

The capacity to tweak PU boards to various thicknesses, varieties, and surface completions guarantees that they can meet explicit undertaking prerequisites. Also, the boards can be planned with heat proof properties by integrating added substances, which is fundamental for consenting to building wellbeing guidelines.

ATTENTION:For your factory,pu sandwich panel offer a practical, cost-effective, and energy efficient solution. They provide excellent insulation, structural durability, fire resistance, and sound control, making them ideal for the demands of industrial settings.

Impecuniousness to fire

While polyurethane itself is a combustible material, current PU sandwich boards are produced with heat proof properties. This is accomplished by involving fireretardant synthetic compounds in the polyurethane froth or by covering the boards with heat proof facings. The expansion of these fire-retardant layers guarantees that the boards are consistent with tough fire wellbeing guidelines in numerous locales.

Heat proof PU sandwich boards can defer the spread of flares, giving tenants extra chance to clear and firemen additional opportunity to control the blast. This causes them a more secure choice for structures that to require high fire insurance guidelines, like schools, clinics, and public structures.

Sound Protection

One more significant advantage of PU sandwich boards is their capacity to give sound protection. The thick design of polyurethane froth hoses commotion, which is especially significant in conditions with elevated degrees of sound contamination, like manufacturing plants, air terminals, and occupied metropolitan regions. By utilizing PU boards for walls, rooftops, or parcels, the transmission of commotion between various regions can be diminished, establishing a calmer and more agreeable climate for laborers or occupants.

This trademark likewise makes PU boards an alluring choice for theaters, show lobbies, and recording studios where sound control is basic.

End

Polyurethane (PU) sandwich boards offer many advantages, including excellent warm protection, underlying strength, imperiousness to fire, sound protection, and plan adaptability. Their lightweight nature and simplicity of establishment decrease development time and expenses, while their sturdiness guarantees long haul execution with negligible support. PU boards are likewise harmless to the ecosystem, with energy-saving properties that add to a decrease in fossil fuel byproducts. Their application across different enterprises, from cold capacity to private lodging, makes them an ideal answer for current development needs. In general, PU sandwich boards give a practical, manageable, and productive structure material that fulfills the needs of both private and modern undertakings.

tagxa

tagxa