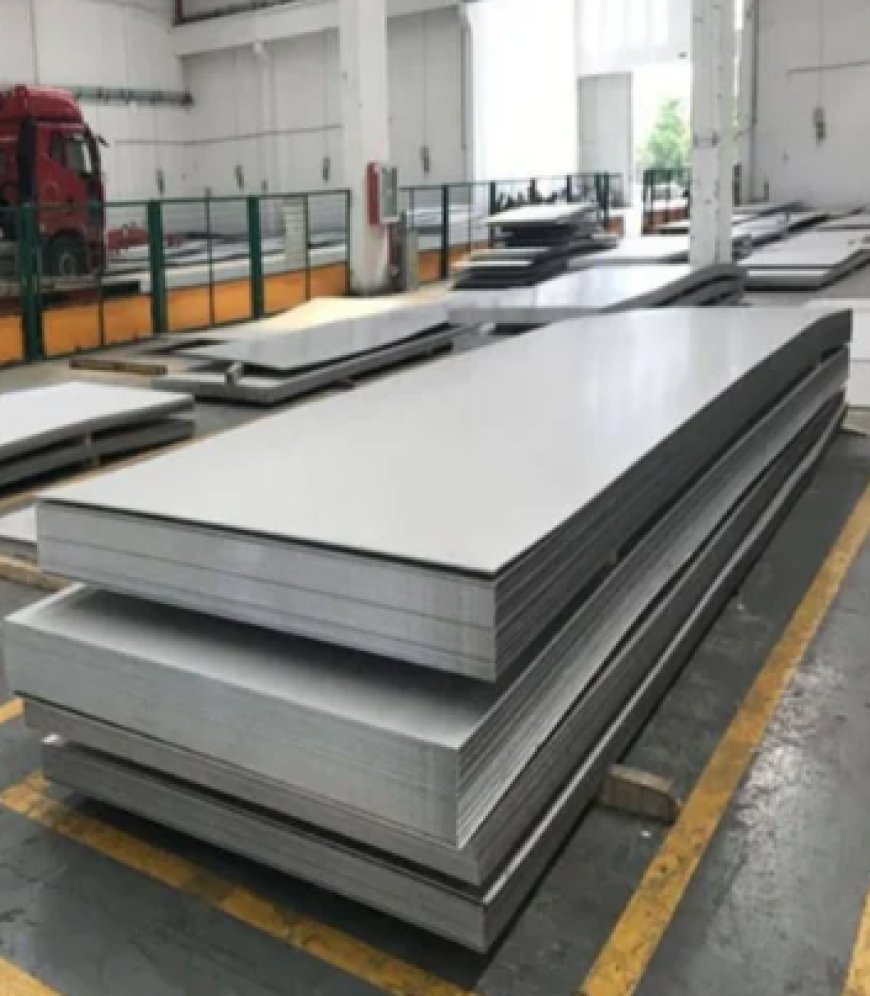

Steel Sheet Pricing: Key Determinants and Smart Procurement Strategies

Steel sheets are a fundamental resource across industries, including manufacturing, construction, automotive, and industrial machinery. Their cost can vary significantly due to numerous factors, making it essential for buyers to understand the variables at play. This knowledge can help businesses manage budgets, plan projects efficiently, and negotiate better deals.

Factors Influencing Steel Sheet Prices

Raw Material Costs

The primary components of steel—iron ore, coal, and scrap metal—drive the base cost of steel sheets. Global demand, particularly in high-growth economies like China or India, can lead to price surges in these raw materials.

Manufacturing Process

-

Hot-Rolled steel sheet prices: Manufactured at high temperatures, they are generally less expensive but suitable for projects requiring basic structural strength.

-

Cold-Rolled Steel Sheets price: These undergo additional processing, resulting in smoother finishes and enhanced precision, which increases their price.

Steel Grades and Coatings

Steel sheets are categorized into different grades based on their strength, composition, and application. For example:

-

High-Strength Low-Alloy (HSLA) Steel: Costlier but offers superior performance.

-

Galvanized Sheets: Coated with zinc to resist corrosion, making them ideal for outdoor use but more expensive.

Global Supply and Demand Trends

Economic activities like infrastructure development or automotive manufacturing heavily influence steel demand. A spike in global construction projects or limited steel production can cause prices to rise sharply.

Transportation and Logistics

Shipping costs for steel sheets are considerable due to their weight and bulk. Proximity to suppliers and the state of logistics infrastructure can significantly affect overall expenses.

Trade Policies and Tariffs

Import duties and trade restrictions imposed by governments to protect domestic steel industries often lead to increased prices for imported steel sheets. For instance, U.S. tariffs on steel imports have historically raised costs for buyers relying on foreign steel.

Strategies to Optimize Steel Sheet Costs

Plan Ahead

Steel prices fluctuate, so scheduling purchases during periods of low demand can lock in more favorable rates.

Buy in Bulk

Large orders often qualify for discounts, reducing the per-unit cost.

Source Locally

Purchasing from nearby suppliers minimizes transportation expenses and supports quicker delivery times.

Monitor Market Trends

Stay informed about global commodity prices, trade policies, and steel production forecasts to make timely purchases.

Diversify Suppliers

Establish relationships with multiple vendors to mitigate risks from supply chain disruptions or pricing inconsistencies.

Conclusion

Steel sheet prices are shaped by a complex interplay of raw material costs, manufacturing techniques, market demand, logistics, and government policies. By understanding these factors and adopting strategic procurement practices, buyers can optimize their investment and secure quality materials for their projects.

If you are looking for best quality tmt bars, please visit our website : www.steeloncall.com or you can contact us through our toll-free number: 18008332929

#steelsheetprices #steelsheetpricetoday #steelsheet #steelsheetprice

vamshidmsoc

vamshidmsoc