Unlocking Precision with High-Quality CNC Turning Machines

CNC turning has revolutionized the manufacturing industry by providing a high level of precision, speed, and efficiency. At the heart of this advanced process is the CNC turning machine, which allows for the precise shaping of materials into a wide array of components used across industries.

CNC turning has revolutionized the manufacturing industry by providing a high level of precision, speed, and efficiency. At the heart of this advanced process is the CNC turning machine, which allows for the precise shaping of materials into a wide array of components used across industries. With its ability to automate complex processes, CNC turning offers manufacturers the opportunity to produce parts with exceptional accuracy and minimal waste.

How CNC Turning Machines Operate

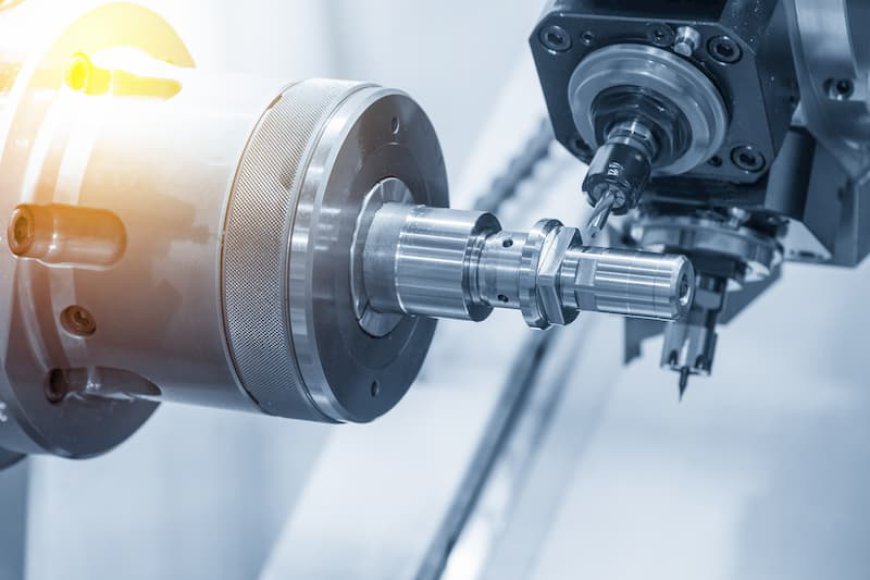

In CNC turning, a material is mounted in a chuck that rotates it at a controlled speed, known as RPM (Rotations Per Minute). A cutting tool is then applied to the rotating material to carefully remove the excess, shaping the part to exact specifications. The automation provided by Computer Numerical Control (CNC) technology enables this process to be both repeatable and highly precise, eliminating the inconsistencies that come with manual machining. The machine’s settings are controlled via a computer program, which ensures that each part is produced with the same level of accuracy.

Key Applications of CNC Turning

CNC turning machines are primarily used to manufacture parts that require rotational symmetry, including cylindrical, hexagonal, and square components. The versatility of CNC turning allows it to be used for a wide range of applications, especially in industries where high precision is crucial. Common parts produced using CNC turning machines include:

- Shafts and Spindles: Essential components in machinery, automotive, and aerospace applications.

- Bushings: Used in mechanical systems to reduce friction and wear.

- Custom Components: Tailored parts with specific features, including intricate internal bores or complex geometries.

The ability of CNC turning machines to produce components with tight tolerances and exact dimensions makes them invaluable in industries such as automotive, aerospace, electronics, and medical device manufacturing.

Advantages of High-Quality CNC Turning Machines

-

Enhanced Productivity: The automation in CNC turning leads to faster production cycles, which ultimately reduces lead times and increases overall production efficiency.

-

Unmatched Precision: CNC turning machines can produce parts with incredibly tight tolerances, ensuring that every part meets the exact specifications required for high-performance applications.

-

Reduced Material Waste: CNC turning machines are designed to optimize material usage, cutting only the necessary amount and reducing scrap, which helps to lower production costs.

-

Labor and Time Savings: The automated nature of CNC turning means that fewer operators are required, and machines can run continuously, resulting in significant savings in labor costs and time.

-

Improved Safety: The controlled environment of CNC turning minimizes the risk of human error and injury, providing a safer alternative to manual machining methods.

-

Lower Skill Requirements: CNC turning machines simplify the machining process, making it easier for operators of varying skill levels to manage the equipment, without compromising quality.

Precision in Every Component

CNC turning is ideal for producing components with rotational symmetry, such as shafts, spindles, and cylinders, as well as parts that require intricate detailing, like internal bores. The adaptability of CNC turning machines makes them a go-to solution for manufacturers that need to produce both simple and complex parts with the highest level of precision.

Why Choose Keytex Machines for Your CNC Turning Needs

Keytex Machines offers high-quality CNC turning machines that provide exceptional performance and durability. We specialize in delivering top-tier CNC equipment that caters to various manufacturing needs, from basic components to intricate, custom parts. By choosing Keytex Machines, manufacturers can be assured of receiving machines that are engineered for precision, reliability, and efficiency.

We take pride in providing our customers with CNC turning solutions that not only meet industry standards but exceed them, delivering high-quality parts at competitive prices. Whether you’re in need of a CNC turning machine for large-scale production or small-scale, high-precision parts, Keytex Machines ensures that each solution is tailored to your exact specifications.

Conclusion

CNC turning machines are integral to modern manufacturing, offering speed, precision, and flexibility. By investing in high-quality CNC turning equipment from Keytex Machines, manufacturers can ensure the production of durable, high-performance parts with minimal waste and maximum efficiency. Keytex Machines stands at the forefront of CNC turning, offering top-tier equipment and solutions designed to meet the highest standards of the industry.