What Are the Advantages of Integrating Nash Liquid Ring Vacuum Pumps with Heat Exchangers?

In modern-day business programs, optimizing machine performance is vital for maintaining productiveness, lowering strength intake, and improving operational performance. One place in which organizations continuously seek improvements is the integration of numerous systems like heat exchangers and Nash liquid ring vacuum pumps. Combining these two additives can cause stepped forward performance and reliability in various industries, from chemical processing to meals production.

This weblog will explore the important thing advantages of integrating Nash liquid ring vacuum pumps with warmth exchangers, specializing in performance, reliability, power financial savings, and upkeep.

Understanding Heat Exchangers and Nash Liquid Ring Vacuum Pumps

Before delving into the advantages of integration, it’s critical to recognize the feature of both warmness exchangers and Nash liquid ring vacuum pumps.

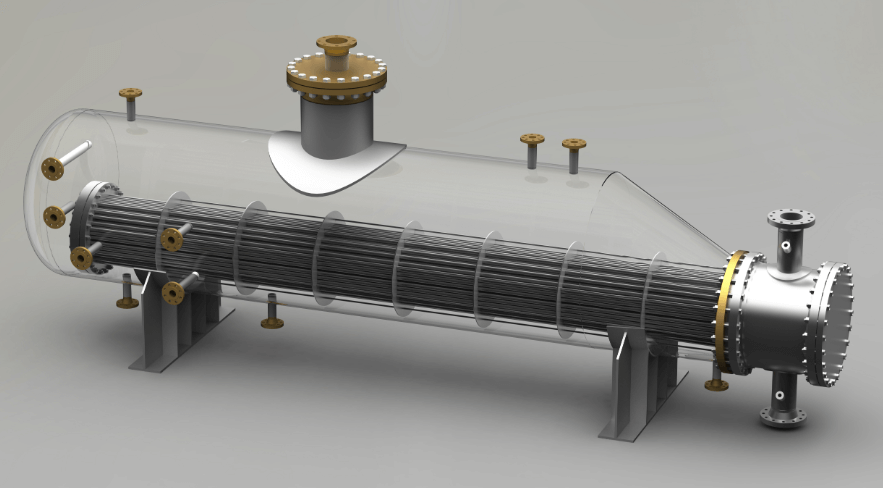

A warmness exchanger is a device used to transfer heat among two or greater fluids. These devices play a critical function in numerous commercial methods, consisting of cooling, heating, and condensation. Heat exchangers are extensively used in programs where retaining particular temperatures or cooling fluids is critical, together with in HVAC systems, energy flowers, and chemical processing.

On the other hand, Nash liquid ring vacuum pumps are a form of high-quality displacement pump designed to put off gases and vapors from a device via creating a vacuum. These pumps make use of a liquid seal, often water, which permits them to function without the need for lubrication. This makes them perfect for packages involving water vapor or different corrosive gases. The Nash liquid ring vacuum pumps are normally utilized in industries which include oil and fuel, chemical processing, and pharmaceutical production.

When combined, these structures can beautify usual performance, presenting extensive blessings throughout diverse sectors.

1. Improved Thermal Efficiency

One of the key advantages of integrating Nash liquid ring vacuum pumps with warmth exchangers is the development in thermal efficiency. Heat exchangers are designed to switch warmth among fluids, and their performance is frequently impacted via the capacity to hold steady stress and temperature tiers.

By the use of Nash liquid ring vacuum pumps, which efficiently lessen stress levels in sure parts of the machine, the warmth switch manner may be optimized. When the vacuum pump gets rid of air and different non-condensable gases from the device, it permits the warmth exchanger to work greater efficaciously, improving the overall warmth change process.

In many industries, this stepped forward thermal performance interprets into better product yields, extra consistent processing, and better typical overall performance.

2. Energy Savings

Energy expenses are a first-rate difficulty for many industries, specially in tactics that require steady heating or cooling. Nash liquid ring vacuum pumps can help reduce power consumption in warmness exchanger structures.

By maintaining the right pressure ranges and correctly evacuating non-condensable gases from the gadget, Nash liquid ring vacuum pumps can permit warmness exchangers to characteristic more correctly. This advanced performance regularly results in a reduction in the amount of power required to attain the desired temperature or warmness transfer, thereby lowering electricity charges.

Furthermore, by using optimizing the operation of warmth exchangers, agencies can avoid electricity-wasting inefficiencies like overheating or overcooling, which is specially essential in industries like petrochemicals or food and beverage processing.

3. Enhanced System Reliability

Reliability is a critical element in any commercial gadget. Nash liquid ring vacuum pumps provide a dependable manner of retaining vacuum stress, even in challenging situations. They are acknowledged for their durability and ability to deal with huge volumes of fuel and vapor without breaking down.

When paired with heat exchangers, this reliability extends to the heat transfer technique. Since Nash liquid ring vacuum pumps can constantly cast off air and non-condensable gases from the system, they ensure that the warmth exchangers work optimally with out disruptions. The steady vacuum strain supplied via these pumps reduces the probabilities of system failure or inefficient performance due to air wallet or vapor lock.

In industries wherein downtime is costly, the combination of Nash liquid ring vacuum pumps with warmness exchangers facilitates keep away from unexpected failures, accordingly enhancing machine uptime and boosting productiveness.

4. Reduced Maintenance Costs

Maintenance is every other vital issue of commercial systems. Both Nash liquid ring vacuum pumps and heat exchangers require normal maintenance to make certain they preserve functioning optimally. However, through integrating those two structures, businesses can reduce renovation charges in numerous methods.

First, the Nash liquid ring vacuum pumps are designed for minimum put on and tear due to their liquid seal era. This approach fewer mechanical additives are subject to failure, decreasing the need for frequent upkeep or replacements. Additionally, Nash liquid ring vacuum pumps typically require less protection than different vacuum pump systems, which makes them a price-effective answer in the long run.

Secondly, considering that warmness exchangers function more successfully with the help of Nash liquid ring vacuum pumps, there may be much less strain located on the gadget, reducing the probability of clogging, overheating, or other renovation problems that regularly stand up from inefficient heat exchange.

5. Environmental Benefits

Integrating Nash liquid ring vacuum pumps with warmth exchangers also brings environmental blessings. In industries consisting of chemical processing and prescribed drugs, where handling emissions and waste gases is essential, Nash liquid ring vacuum pumps assist get rid of non-condensable gases from the gadget. These gases, if left unchecked, can intrude with the heat exchange procedure and can make a contribution to environmental pollution.

By the use of Nash liquid ring vacuum pumps to correctly evacuate unwanted gases, the general environmental footprint of the system can be decreased. This is particularly beneficial for organizations aiming to satisfy environmental rules or reduce their average power intake.

6. Better Control Over Process Conditions

The combination of Nash liquid ring vacuum pumps and heat exchangers gives operators extra manipulate over manner situations. By handling stress, temperature, and gasoline content more successfully, organizations can optimize conditions for precise applications.

For instance, inside the pharmaceutical enterprise, where particular temperature manipulate is essential, Nash liquid ring vacuum pumps help make certain that the warmth exchangers preserve the precise temperature and pressure for product stability. This ends in higher-high-quality merchandise and decreases the threat of production mistakes.

Conclusion

Integrating Nash liquid ring vacuum pumps with warmth exchangers gives several blessings, from enhanced thermal performance and energy savings to stepped forward reliability and decreased renovation fees. In industries where steady temperature control and green warmness switch are essential, this mixture can result in extensive improvements in gadget performance and productiveness.

By leveraging the capabilities of Nash liquid ring vacuum pumps, corporations can optimize the operation of heat exchangers, making them more energy-efficient, dependable, and value-effective. Ultimately, this integration allows companies to lessen costs, improve product exceptional, and increase their operational performance.

uklalyrics

uklalyrics