What Services Should Leading Heat Exchanger Suppliers Offer Beyond Products?

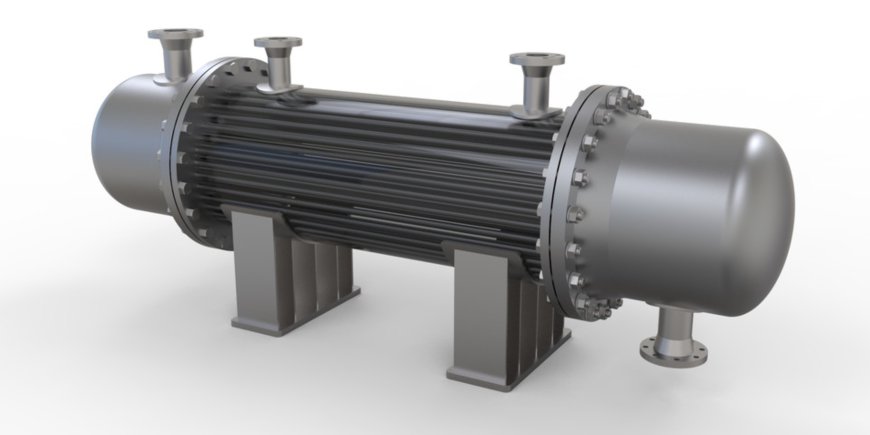

In today’s aggressive market, heat exchanger suppliers want to provide greater than just excellent merchandise. Customers increasingly are looking for providers who offer a wide variety of offerings to ensure ultimate performance, reduce maintenance costs, and expand the lifespan of equipment. From installation to maintenance and customization, providers that go beyond product delivery create long-term value for their customers. This article explores the critical services that top suppliers must provide, especially focusing on shell & tube heat exchangers and their related needs.

1. Comprehensive Installation Support

For heat exchangers, particularly complex systems like shell & tube heat exchanger, installation plays a vital role in ensuring operational performance. Leading heat exchanger suppliers must offer:

- On-site installation support to assist customers in integrating new equipment into existing systems.

- Training for staff and technicians to ensure proper handling and installation procedures.

- Post-installation inspection to verify that the unit functions according to design specifications.

Providing expert installation services reduces the likelihood of early malfunctions and optimizes the machine’s performance from the outset.

2. Customization Services

No industries have the same heat exchange necessities. For example, refineries, food processing plants, and chemical factories all have specific needs. Therefore, heat exchanger providers should offer:

- Customized designs to fit particular commercial processes and design requirements.

- Material selection guidance based on operational temperatures, pressure levels, and chemical exposure.

- Tailored configurations for specific models like shell & tube heat exchangers, ensuring they meet the specific demands of the application.

Customization not only improves performance but also ensures that the equipment meets regulatory standards and safety requirements.

3. Preventive Maintenance Programs

Regular maintenance is crucial to preventing failures and extending the life of shell & tube heat exchangers. Top providers must offer:

- Scheduled inspections and maintenance plans to detect potential problems early.

- Cleaning services to eliminate fouling and debris that may affect performance.

- Replacement of worn components, such as gaskets and tubes, to maintain efficiency.

A proactive maintenance approach minimizes downtime, extends system lifespan, and reduces operational costs over time.

4. Technical Support and Troubleshooting

Even the most well-maintained heat exchangers can experience issues. Reliable heat exchanger suppliers need to provide:

- 24/7 technical support to address urgent operational challenges.

- Remote monitoring solutions to detect issues in real time and offer quick fixes.

- On-site repair services for situations where remote troubleshooting is inadequate.

Access to reliable technical support ensures smooth operations and quick resolution of any technical problems that may arise.

5. Spare Parts Availability

Ensuring the availability of critical spare parts is essential to avoid long downtimes. Suppliers should maintain an inventory of:

- Common replacement parts such as, seals, and gaskets for shell & tube heat exchangers.

- Emergency stock services to supply parts quickly when needed.

- Compatibility tests to ensure the provided components integrate seamlessly with existing systems.

Fast access to spare parts reduces downtime, allowing industries to maintain uninterrupted operations.

6. Energy Efficiency Audits

With growing concerns about electricity consumption, heat exchanger systems must operate efficiently. Top heat exchanger providers should offer:

- Energy audits to assess the system’s performance.

- Recommendations for improvements or retrofits to enhance energy savings.

- Monitoring equipment to track performance and energy consumption over time.

These audits help organizations reduce operational costs and align with environmental requirements.

7. Retrofitting and System Upgrades

Technology advances rapidly, and outdated equipment can lead to inefficiencies. Suppliers should provide:

- Retrofit services to replace existing shell & tube heat exchangers with modern components.

- System upgrades to improve capacity, reliability, and energy efficiency.

- Consultations on compliance with the current industry regulations and safety standards.

Retrofitting older systems is a cost-effective way to enhance performance without requiring a full replacement.

8. Training Programs for Operational Teams

Training helps operational teams use heat exchangers effectively and safely. Top providers should offer:

- In-depth training programs focused on both operation and maintenance.

- Workshops and online courses for continuous learning.

- Documentation and manuals to guide technicians on specific tasks.

A well-trained workforce can prevent costly errors and ensure the equipment operates at its best.

9. Performance Monitoring Solutions

Advanced monitoring systems can track the health and performance of shell & tube heat exchangers. Leading suppliers must offer:

- IoT-enabled monitoring equipment for real-time data collection and analysis.

- Predictive maintenance software to forecast potential failures.

- Performance reports to help organizations make informed decisions on maintenance schedules and upgrades.

These solutions help industries optimize performance and reduce downtime.

10. Regulatory Compliance Assistance

Heat exchangers must comply with industry regulations, especially those utilized in critical industries like energy generation and pharmaceuticals. Suppliers need to assist with:

- Documentation and certifications to meet local and international requirements.

- Inspections and audits to ensure compliance throughout the product’s lifecycle.

- Consultation on regulatory updates to keep clients informed of recent requirements.

Proper compliance reduces legal risks and ensures smooth operations.

Conclusion

In today’s market, leading heat exchanger providers must go beyond merely delivering products. They need to offer a wide range of services to meet the evolving needs of industries. From installation and customization to preventive maintenance and technical support, these services ensure that shell & tube heat exchangers and other systems operate efficiently and reliably. Suppliers who offer energy audits, spare parts availability, training programs, and compliance assistance set themselves apart by delivering long-term value to their clients. Investing in a supplier that provides comprehensive services ensures that businesses can achieve better performance, reduced downtime, and enhanced operational safety over the lifetime of their equipment.

uklalyrics

uklalyrics