Optimize Inventory with High-Quality ASRS Pallet Systems

In today’s fast-paced business environment, efficient inventory management is crucial for maintaining a competitive edge. Automated Storage and Retrieval Systems (ASRS) are revolutionizing how warehouses manage their inventory, providing a sophisticated solution to optimize storage, streamline operations, and improve overall productivity. In this blog, we will explore the benefits of ASRS pallets and how they can transform your inventory management process.

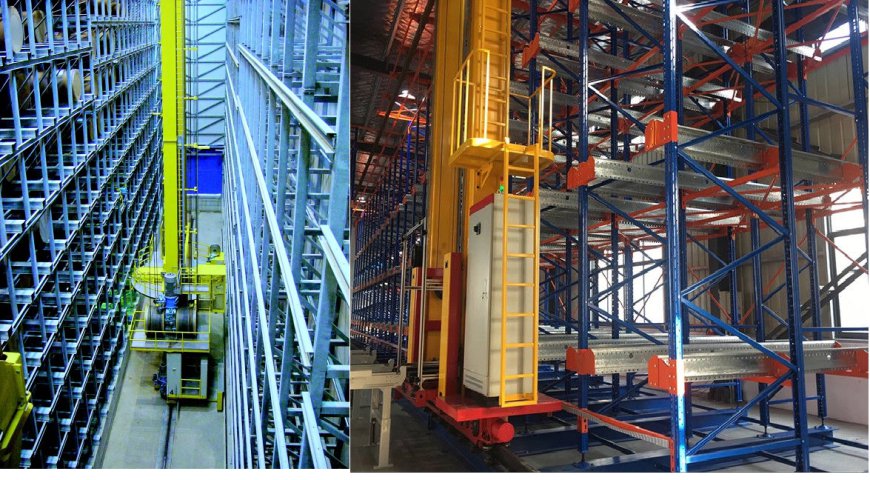

Understanding ASRS Pallet Systems

ASRS pallet systems are automated systems designed to handle the storage and retrieval of goods in a warehouse setting. These systems utilize a combination of robotics, conveyors, and computer software to manage inventory automatically. By integrating ASRS pallets into your operations, you can enhance efficiency, reduce labor costs, and minimize errors in inventory handling.

The technology behind ASRS systems allows for precise control over inventory locations, making it easier to track products and manage stock levels. ASRS pallets are typically designed to accommodate various sizes and weights of products, ensuring that your warehouse can adapt to changing inventory needs.

Key Benefits of ASRS Pallet Systems

1. Increased Storage Capacity

One of the most significant advantages of using ASRS pallets is their ability to maximize storage capacity. Traditional storage methods often lead to wasted space due to inefficient shelving and manual handling. ASRS systems utilize vertical space and dense storage techniques, allowing for higher storage densities. This optimization enables businesses to store more products within the same footprint, ultimately reducing the need for additional warehouse space.

2. Improved Inventory Accuracy

Inventory accuracy is critical for successful operations. With ASRS pallet systems, the likelihood of human error is significantly reduced. Automated systems can accurately track inventory movements and provide real-time updates, ensuring that stock levels are always up to date. This accuracy minimizes the chances of overstocking or stockouts, leading to better customer satisfaction and enhanced operational efficiency.

3. Enhanced Speed and Efficiency

ASRS pallet systems streamline the process of retrieving and storing items, leading to faster order fulfillment times. Automated systems can operate 24/7 without the need for breaks, ensuring that your warehouse runs smoothly at all times. This increased speed not only improves productivity but also allows businesses to respond quickly to customer demands, providing a competitive advantage in the marketplace.

4. Reduced Labor Costs

Labor costs can be one of the most significant expenses in warehouse operations. By implementing ASRS pallet systems, businesses can significantly reduce their reliance on manual labor for inventory management. Automated systems require fewer personnel for operations, allowing your workforce to focus on higher-value tasks such as quality control and customer service. This shift can lead to substantial cost savings while enhancing overall operational efficiency.

5. Better Safety Standards

Safety is a paramount concern in any warehouse setting. ASRS pallet systems contribute to a safer work environment by reducing the need for manual handling of heavy items. Automation minimizes the risk of workplace accidents and injuries associated with lifting and moving products. Furthermore, these systems are designed with safety features, ensuring that both employees and inventory remain protected during operations.

Implementing ASRS Pallet Systems

When considering the implementation of ASRS pallet systems, it’s essential to conduct a thorough analysis of your current inventory management processes. Assess your storage capacity, product types, and order fulfillment needs to determine the best ASRS solution for your business. Partnering with a reputable ASRS manufacturer can provide valuable insights into selecting the right system tailored to your specific requirements.

Additionally, proper training for your staff is crucial to ensure a smooth transition to automated systems. Familiarizing employees with the technology and its operations will help them adapt quickly, maximizing the benefits of ASRS pallets.

Conclusion

Investing in high-quality ASRS pallet systems can dramatically optimize your inventory management, leading to increased efficiency, accuracy, and cost savings. By leveraging automation technology, businesses can improve their storage capacity while enhancing safety and reducing labor costs. As the demand for efficient inventory management continues to grow, integrating ASRS pallets into your operations may be the key to achieving a competitive edge in the marketplace. Embrace the future of inventory management and discover the transformative benefits that ASRS pallet systems can offer your business.