USP 1790 Particles for Visual Inspection, Visual Inspection Standards, and Visual Inspection Sets in Germany

Visual inspection is essential to pharmaceutical quality assurance, ensuring every product meets stringent safety and efficacy standards vital to the healthcare industry. Supporting this mission, the Knapp Kit for Visual Inspection has become a trusted solution. In this article, we’ll delve into the importance of Knapp Kits, their role in visual inspection, and their contribution to USP 1790 compliance.

In industries like pharmaceuticals, medical devices, and food production, ensuring product quality and safety is essential. One of the most effective ways to maintain this high level of quality is through visual inspection. With guidelines like USP 1790 Particles for visual inspection, and the use of visual inspection sets in Germany, businesses can ensure that their products are free from harmful particles and defects.

In this blog, we will cover the importance of visual inspection, the global standards that guide these processes, and the technology involved, such as visual inspection sets in Germany. We will also focus on the role of USP 1790 Particles for visual inspection in ensuring particle detection in sterile pharmaceutical products.

What is Visual Inspection?

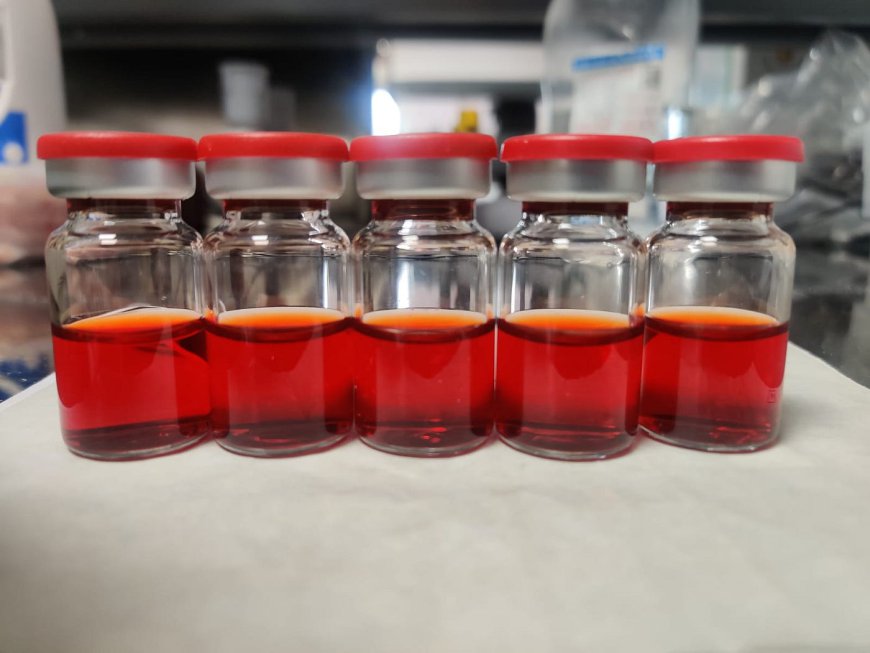

Visual inspection is a non-destructive testing process where products are examined for visible defects, contamination, and particle presence. In industries like pharmaceuticals, this process is vital to ensure that products are safe for consumers. For instance, when a company produces injectable medicines, they must be certain that no particles or defects are present in the vials, as even a small contaminant can harm patients.

USP 1790 Particles for Visual Inspection

The USP 1790 guideline is a globally recognized standard that deals with visual inspection in the pharmaceutical industry, specifically focusing on particle contamination. It sets clear procedures for detecting particles in sterile products, such as vials and ampoules. Let’s explore its key features.

What is USP 1790?

USP 1790 is a chapter in the United States Pharmacopeia (USP) that focuses on visual inspection of sterile products. It outlines methods for detecting visible particles that may contaminate injectable medicines. The guideline specifies how to perform inspections and details the minimum standards for detecting and managing particle contamination.

What Are the Key Criteria of USP 1790?

- Particle Size Detection: According to USP 1790 Particles for visual inspection, particles as small as 50 microns should be detectable under proper lighting conditions.

- Lighting Requirements: USP 1790 specifies that the lighting during inspection must be between 2000 and 3750 lux, which allows inspectors to detect small particles effectively.

- Inspection Methodology: The guidelines call for both manual and automated inspections, ensuring that all products meet the stringent standards for safety and quality.

By following USP 1790 guidelines, companies can ensure that their products are free from visible particles and meet the necessary safety standards, especially in industries where sterility is critical.

Visual Inspection Standards

Global visual inspection standards are designed to ensure consistency and accuracy when checking products for defects or contamination. These standards apply to various industries, including pharmaceuticals, food production, and manufacturing. Let’s take a closer look at the requirements for visual inspection.

What Are Visual Inspection Standards?

Visual inspection standards are guidelines that outline how products should be inspected for defects. These standards ensure that inspections are conducted uniformly and that any product defects are properly identified and classified. Some of the most recognized visual inspection standards include:

- ISO 14644: This standard is widely used in cleanrooms and pharmaceutical environments to control contamination.

- USP 1790: As discussed earlier, this standard focuses on particle detection in sterile products.

- ASTM E1444: This is a method for conducting visual inspections and includes guidelines for lighting, inspector training, and inspection distances.

Why Are Visual Inspection Standards Important?

- Product Safety: Visual inspection standards ensure that defects and particles are detected before products reach consumers, reducing the risk of harm.

- Consistency: Following global standards ensures that inspections are performed the same way every time, which helps maintain product quality.

- Compliance: By adhering to standards such as USP 1790 and ISO 14644, companies meet regulatory requirements, which is essential for product approval in various markets.

What Are the Key Requirements for Visual Inspection?

- Proper Lighting: Inspection areas must have adequate lighting, typically between 2000 and 3750 lux, to ensure that small particles can be detected.

- Trained Inspectors: Personnel conducting visual inspections must be well-trained in identifying defects, contamination, and particle presence.

- Clean Environments: Inspections must take place in clean, controlled environments to avoid introducing new contaminants.

- Documentation: Any defects or particles found during the inspection must be documented and classified based on severity (critical, major, or minor).

Visual Inspection Sets in Germany

Germany is known for its advanced technology and precision manufacturing. This expertise extends to the development and use of visual inspection sets in Germany, particularly in industries like pharmaceuticals and medical devices. Let’s explore how these systems work and why they are essential.

What Are Visual Inspection Sets?

A visual inspection set refers to the equipment used to perform visual inspections. In Germany, these systems are highly advanced, using both manual and automated technologies to ensure that products are free from defects and contaminants. These sets typically include:

- Lighting Systems: High-intensity lights (between 2000 and 3750 lux) that allow inspectors to see even the smallest particles.

- Magnification Tools: Magnifying glasses or microscopes are often used to spot tiny defects in products such as vials and ampoules.

- Turntables: These devices rotate the product during inspection, ensuring that all sides of the product are examined.

- Vision Systems: Automated systems equipped with cameras and software that detect defects automatically, providing a fast and accurate inspection process.

Why Are Visual Inspection Sets in Germany Important?

Germany is a global leader in precision manufacturing and high-quality production. The use of visual inspection sets in Germany ensures that products like medicines, medical devices, and food items meet the strictest quality standards. These systems help detect defects early, preventing faulty products from reaching consumers.

What Industries Use Visual Inspection Sets in Germany?

- Pharmaceuticals: Visual inspection is critical for detecting particles and defects in vials, ampoules, and other sterile containers.

- Medical Devices: Surgical instruments, implants, and other medical devices must be inspected to ensure they are free from defects that could harm patients.

- Food Production: In the food industry, visual inspection helps detect contamination or packaging defects.

Key Visual Inspection Procedures in the Pharmaceutical Industry

Visual inspection is a critical step in pharmaceutical production, ensuring that sterile products like vials and ampoules are free from particles and defects. The procedure usually involves the following steps:

- Preparation: The product is cleaned, and the inspection environment is prepared with proper lighting and equipment.

- Manual or Automated Inspection: Depending on the product, either trained personnel or automated systems perform the inspection. In manual inspection, inspectors carefully rotate the product and look for cracks, particles, or discoloration.

- Documentation: Any defects are recorded, and the product is classified as either acceptable or needing further investigation.

- Post-Inspection: Products that pass the visual inspection are cleared for packaging and distribution, while defective products are removed for further testing or disposal.

Conclusion

Visual inspection plays a crucial role in maintaining product quality and safety, especially in industries like pharmaceuticals. By following global visual inspection standards and using advanced visual inspection sets in Germany, companies can ensure that their products meet the highest safety and quality standards.

The USP 1790 Particles for visual inspection guideline specifically focus on detecting particles in sterile products, helping companies comply with strict safety regulations. With proper lighting, trained inspectors, and advanced vision systems, visual inspection is an essential process that helps keep consumers safe.

At FTI Incorporation, we are committed to following these standards and providing high-quality visual inspection services, whether in Germany or elsewhere. Our use of advanced technology and adherence to strict guidelines ensures that our clients receive the best possible service, keeping their products safe and compliant with industry regulations.

jamessmithjimmy12

jamessmithjimmy12